Footing Design

Once column loads have been calculated, Tribli provides a powerful range of design functions to assist engineers in the sizing and design of concrete pad footings.

Note

Tribli applies an additional factor of safety to all loads prior to being used in any of Tribli's design functions including; column, wall, pad footing, column transition and punching shear design. This value defaults to 1.20, but can be changed by the user in settings or by clicking on the text in the bottom right hand corner of the screen.

Footing Strength and Bearing Checks

-

Create the Tribli model geometry and calculate loads as per the load calculation workflow. These loads will form the basis of the design functions outlined in this article.

-

Prior to completing pad footing checks, ensure that the correct allowable soil bearing capacity has been input for each pad. Tribli defines the allowable bearing capacity as an instance parameter of individual pad footings in order to allow for the possibility of varying soil capacity across the site. Select all pads, right-click on the background and select properties to bring up the properties dialog for all selected footings. In the properties dialog, change the soil allowable bearing capacity to the desired value, as defined in the project geotechnical report, then close the dialog by clicking 'OK'.

-

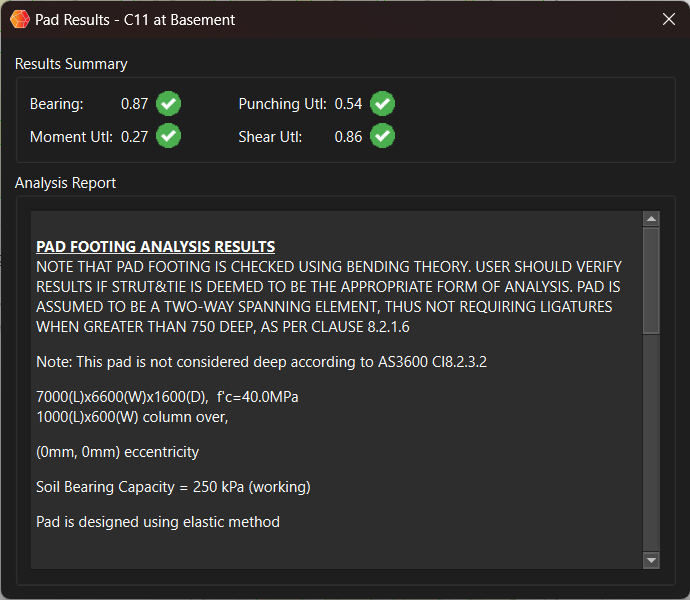

To check the structural and geotechnical capacity of a single footing, right click on a footing and select 'Inspect Capacity'. A design summary of the selected pad will be displayed showing a strength and bearing utilisation summary and text design report.

-

To complete a design check of all footings, select Check Pad Footings from the Design menu. Once complete, go to the element property visibility dialog and turn on 'Bearing Utilisation' and 'Structural Utilisation' under the pad footing section. The footing utilisations will be shown in the graphics view, with a utilisation of less than 1.0 indicating the pad has passed strength checks, and a value greater than 1.0 indicating it has failed. The utilisation for failed pads will be displayed in red. The bearing utilisation displays the geotechnical utilisation of the pad, whereas the structural utilisation displays the ultimate strength utilisation (bending, beam shear and punching) of the pad.

-

Footings that fail design checks can have their size, reinforcement or concrete strength increased in the footing properties dialog. This can be accessed by either double-clicking on the footings or by right clicking and selecting 'Properties' from the drop down menu. Once the footing properties have been modified, the design results for that footing will be deleted and the utilisation will be reported as '0.0'. Right click on the pad and select 'Check Footing' to redo the pad footing design checks. The new structural and bearing utilisations will be displayed in the graphics view.

Pad Footing Optimisation

As well as checking pre-defined pad footings, Tribli can also run an optimisation process to reduce footing sizes to their structural and geotechnical minimum.

As with many concrete elements, there is always a trade-off between depth and reinforcement quantity which must be considered when sizing pad footings. Tribli has three settings that dictate how aggressive the software is in trying to minimise footing depth; 'Min Depth', 'Balanced' and 'Min Steel'. 'Min Depth' attempts to minimise the depth of the footing at all costs, 'Min Steel' sizes the depth of the footing such that the minimum area of steel for a given footing depth is sufficient for the bending and shear requirements and 'Balanced' provides a depth value approximately half way between these two extremes. The default setting is 'Min Steel', however this can be changed under the optimisation tab of the Tribli settings.

Optimising Individual Pads

Select 'Optimise -> All Pads' from the design menu to perform the optimisation. The pad footing size will be optimised based on the ultimate limit state (ULS) strength and working loads. The pad aspect ratio will be set based on the dimensions of the column over, by attempting to achieve an even pad 'cantilever' around all sides of the column. Alternatively, individual footings can be optimised by right clicking and selecting 'Optimise' from the dropdown menu.

Optimising Footings in Groups

In practice, it is more common to group pad footings by their structural demand in order to reduce the number of unique footing sizes in the building. Tribli makes use of pad types to rationalise the number of unique pad sizes. Each pad footing can be assigned to a pad type, after which the pad type parameters (Length/Width/Depth, concrete grade, reinforcement etc.) will no longer be able to be directly edited for that pad, and will instead reference the properties of the defined pad type.

To manually assign footings to pad types, double-click on a footing to enter its properties dialog. In the top left of the dialog is a drop-down menu where the user can select the pad type to which this footing is to be assigned. If the pad type does not exist, click the 'Add Type' button to create a type and assign it to the current footing.

To automatically group pad footings into pad types based on the axial load of the column landing on the footing, select all pads that require grouping, then select Auto-Create Pad Types from Selection from the Tools menu. The user will then be asked how many pad types should be created. Pad types will be created and their size optimised so that all pad footings assigned to that type pass ULS strength and geotechnical bearing checks.

If pad types have already been assigned, footings can also be optimised by type by selecting Optimise -> All Pad Types from the Design menu.

Optimising Pad Reinforcement

Pad footing reinforcement can be manually input via the pad properties dialog, however usually the user will want Tribli to design the pad reinforcement automatically.

To design pad footing reinforcement, select 'Optimise -> All Pad Reinforcement' from the Design menu. Otherwise, to design the reinforcement for a single pad, right-click on that pad and select 'Design Reinforcement' from the drop-down menu.

Pad footings may not always be reinforceable for a given pad size and load. In these instances, an error dialog will pop up informing the user that the footing is unreinforceable.

Note that pad and pad type optimisation functions will optimise the pad reinforcement as well as the size of the footing, so reinforcement optimisation is generally only required when the footing size has been manually adjusted.